Note: The term HSS for this tool category comes from the utilised drill material. High speed steel (HSS) is a high alloy tool steel extremely resistant to wear due to its manufacturing process and is dimensionally stable up to approx. 600°C. Cutting oil or coolant emulsion should be used as cooling lubricant, when machining steel. Spirits or petroleum should be used for aluminium. Normally, plastic and wood can be dry-machined.

NO 28 864

NO 28 852

NO 28 854

NO 28 856

NO 28 858

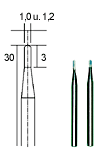

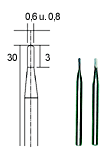

HSS drill bits

Selected steel quality. Purpose-made stable construction with high concentricity. Shaft and bit are manufactured from a one-piece blank. High hardness for optimum life expectancy and elasticity. For drilling metal, non-ferrous metals, plastic, PC cards and wood. Work speeds: soft materials approx. 8,000rpm, hard materials approx. 3,000rpm. Ø shanks 2.35mm. Rotational speed see table.

NO 28 874

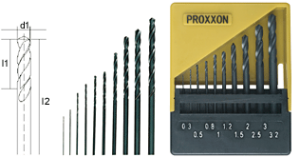

HSS twist drill in storage case

10-piece set. Similar to DIN 338. Ø 0.3 – 0.5 – 0.8 – 1 – 1.2 – 1.5 – 2 – 2.5 – 3 – 3.2mm. For drilling non-ferrous metal, steel and stainless steel. In labelled cassette with fold back and stand function. For clamping we recommend our3-jaw drill chuck. Rotational speed see table.

NO 28 876

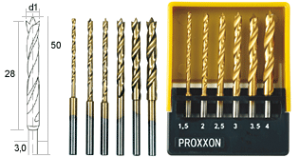

HSS twist drill set with centring pin

Ø 1.5 – 2.0 – 2.5 – 3.0 – 3.5 – 4.0mm. For precision tapping of wood and plastics; also non-ferrous metal, steel and stainless steel sheets. Titanium coating reduces friction and increases service life. Shaft Ø 3mm, 6-piece set. Rotational speed see table.

For steel, glass, circuit boards: Tungsten carbide drills

NO 28 324

NO 28 326

NO 28 328

Tungsten carbide drills

Made of wear-resistant tungsten carbide. For drilling glass, semiprecious stones, porcelain, ceramics, marble and other hard stones. The hard stones are subdivided according to the degree of hardness from 1 – 10. Tungsten carbide can be used up to hardness degree 6. Drilling hard stones with a hardness degree of more than 6 calls for the use of diamond tools. Shaft Ø 3.0mm. With ideal cutting angle of 6°. Rotational speed see table.

NO 28 320

NO 28 321

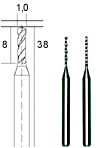

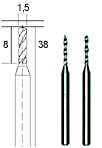

Tungsten carbide milling drills (spear drills)

For drilling, milling and cutting fibre glass or PERTINAX circuit boards. Also for drilling pearls and similar. Shaft Ø 2.35mm. Rotational speed see table.

For glass, ceramics, plastic: Diamond tools

NO 28 255

Diamond twist drills

For drilling holes in (semi) precious stones, etc. Shaft Ø 2.35mm.